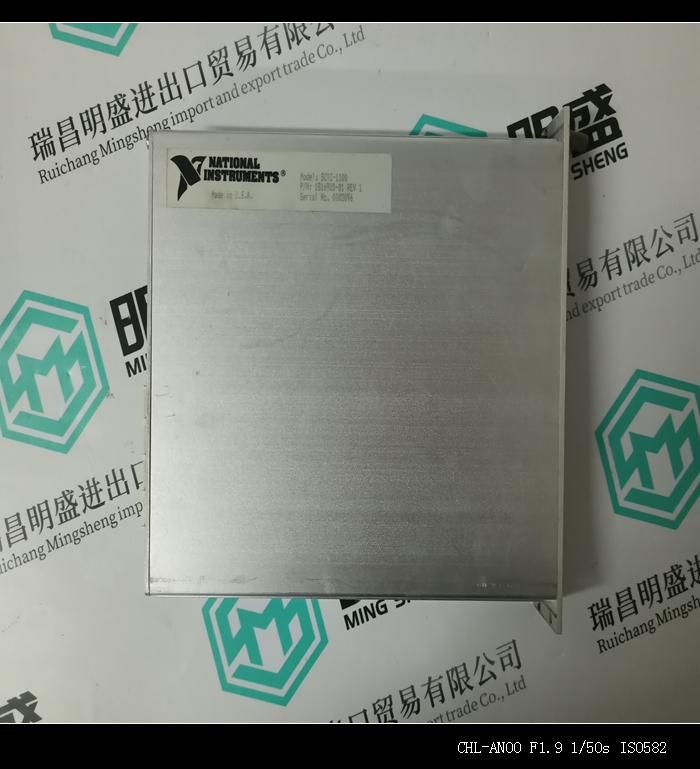

SCXI-1141 182610D-01控制系統(tǒng)卡件模塊庫存

類目:RELIANCE

型號:SCXI-1141 182610D-01

全國服務(wù)熱線:15270269218

手機:15270269218

微信:15270269218

QQ:3136378118

Email:[email protected]