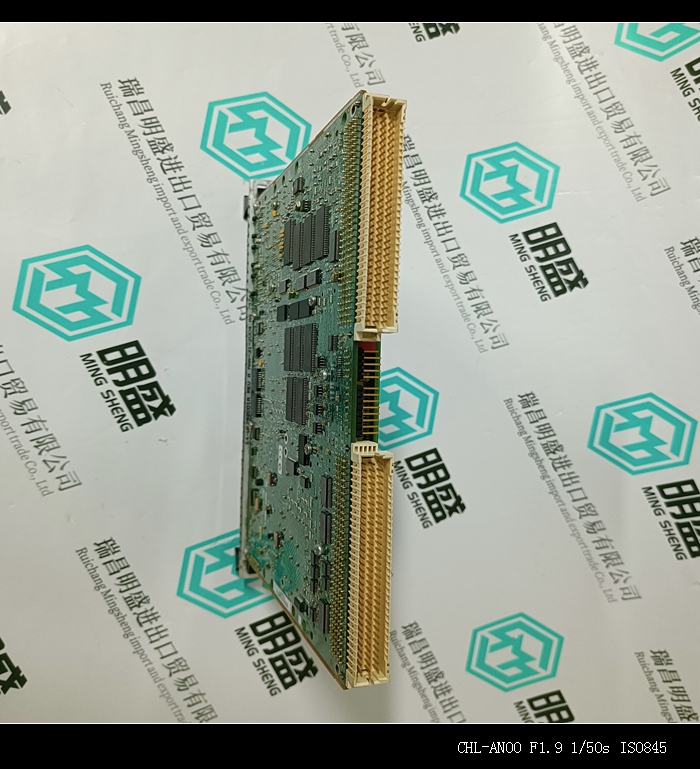

MVME162P-344E現(xiàn)貨PLC自動化卡件

類目:RELIANCE

型號:MVME162P-344E

全國服務(wù)熱線:15270269218

手機(jī):15270269218

微信:15270269218

QQ:3136378118

Email:[email protected]